Recently we read about the involvement of various Austrians in regard to potential parentage of the Volkswagen. Inspired by an article sent to me by reader George Ferencz, let’s explore the life of an Austrian who undoubtedly made an indirect contribution to Volkswagen – along with likely every other brand of automobile produced worldwide after 1929.

His name was Oscar Ulysses Zerk.

Zerk was born as Oscar Zerkowitz in Vienna on May 16, 1878. Zerk’s father, Barnhard, was in the textile business and his family had possessed a degree of prominence since the days of the Holy Roman Empire. Incidentally, Oscar had an older brother, Adolf, who would later become a well-known photographer. Some sources list a second brother named Max.

For reasons never determined during researching this article, Zerk was not accepted to any institution of higher learning. Apparently the intervention of Emperor Franz Josef changed this, allowing Zerk to attend college in the city of Brno in what is currently the South Moravian Region of the Czech Republic. It was during this time Zerk invented an electrically controlled loom for weaving brocade fabric and employed it at his father’s factory.

At some point after graduation, Zerk spent several years working in the English textile industry and returned to Austria around 1905. It was at this point the automobile industry caught his eye. Zerk had soon designed a six-cylinder engine along with an automatic transmission. However, nothing can be found for whom these designs may have been intended as well as if any of it came to fruition.

Zerk was intrigued with steam propulsion and in 1907 came to the United States to study the steam powered cars being produced by White Motor Company in Cleveland, Ohio. Zerk’s trip across the Atlantic was aboard the RMS Lusitania, the ship whose sinking would later serve as the catalyst for the United States entering World War I.

The choice of studying White branded cars is an interesting one. White Motor Company was established by Rollin White in Cleveland, Ohio, and was an offshoot of a company his father, Thomas, had founded. Thomas H. White had founded the White Sewing Machine Company, making for a degree of commonality between Zerk and the younger White as both had fathers involved with the textile industry.

As for the White automobile, it started in a corner of the White sewing machine factory. On July 4, 1905, a White steamer would set a speed record of 73.75 mph. A White steamer was also one of the first automobiles used in the White House fleet. In 1907, President Theodore Roosevelt allowed use of one by the Secret Service when following his carriage. Later, President William Howard Taft had one purchased, enjoying his ability to blast steam at reporters he found annoying.

Zerk’s trip to the United States proved to be fruitful. He was intrigued with the lubrication methods being employed on automobiles at the time, convinced he could improve upon it. Zerk subsequently founded a company in Cleveland, Ohio, and began production of an early version of the well-known Zerk grease fitting. However, Zerk was forced out of the company in 1913.

Zerk returned to Austria and entered into military service due to World War I. After the war Zerk married and returned to the United States.

In 1924, Zerk’s company, Allyne-Zerk, was purchased by Stewart-Warner of Chicago. Whether Allyne-Zerk was Zerk’s original company, or a second one he helped create, has not been able to be determined.

It appears Zerk relocated to Chicago as part of the acquisition.

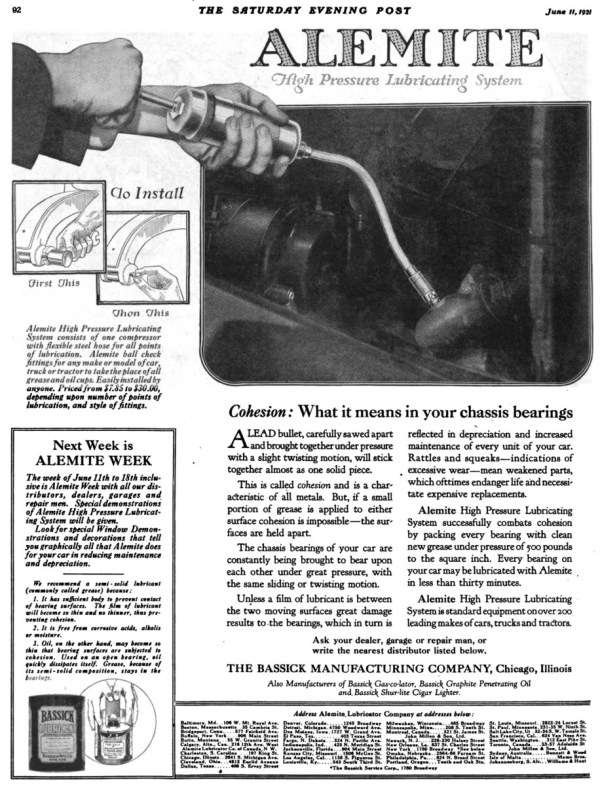

As part of this new company, Zerk was a stockholder and consulting engineer. At that time, Stewart-Warner owned the Alemite system, itself a form of lubrication system which had been developed subsequent to World War I. Zerk acquired a patent (ultimately one of around 200 or so he would hold) for his updated Zerk fitting in 1929. This, combined with the Alemite system, was quite the boon for lubrication in all manner of machinery. It was so popular, the word “alemite” was considered to be a verb for a while during the 1930s.

Some further clarification is needed. The initial Alemite system employed grease fittings. However, the Alemite company deemed the fittings developed by Oscar Zerk as being superior to the Alemite fittings.

Additionally, the ad above could appear to be misleading given its reference to Bassick Manufacturing Company. Edward (although there has been reference to him as “Edgar”) Bassick owned Alemite but was also associated with John K. Stewart, owner of the Stewart Company. Stewart, a maker of speedometers used in the Ford Model T, along with other automotive instruments, had purchased the Warner Instrument Company, creating Stewart-Warner. All the various acquisitions make things tricky to navigate.

Tiring of Chicago, Zerk relocated to Kenosha, Wisconsin, in 1939. He purchased the mansion which had belonged to Henry S. Cooper, one of the three brothers who founded Cooper Underwear Company, which is today known as Jockey International. Zerk dubbed the house and property as the “Dunmovin’ Estate”.

Zerk, suddenly one of the five richest persons in Kenosha County, drastically remodeled the house after his purchase. It was ultimately a private museum of his various collections.

It must be pointed out Zerk was a multitalented man. In addition to his contributions to machinery lubrication, Zerk made developments in hosiery, brake systems for trolley cars, faster freezing ice cube trays, vibration resistant camera tripods, and automotive refrigeration. He even developed a personal sized coffee bean grinder decades before anyone else did so, but Zerk never saw a need for further expansion of the idea beyond his home use.

Thus, Zerk had an abundance of talents and interests.

But it was the events of February 8, 1954, which help lend the most insight into the person who was the then seventy-five year old Zerk.

It was like any other night. Zerk, widowed at the time, was reading upstairs after his staff had gone home. It was around 6:30 pm when three armed persons entered through an unlocked side door. They rushed into the room where Zerk was sitting and threw a towel over his head. Zerk, however, had had ample time to study their features. He would later relate all three were between thirty-five and forty years of age, all were 5’6″ to 5’8″ tall, and the heaviest was around 185 pounds.

The three tied Zerk to a chair and demanded to know where his safe was located. Saying he did not have one, the trio found keys to a closet than contained a key set to open his various display cases throughout the house. Zerk knew they were informed as the trio knew where to look to obtain his late wife’s mink stole.

The criminals took somewhere between 500 and 1,000 items. Zerk had amassed a very impressive collection of Oriental jade, diamonds, sterling silver, and the largest privately owned collection of carved ivory in the United States.

The burglary lasted until roughly 8 pm when the trio loaded up, taking $25 from Zerk’s wallet along with his 1951 Chevrolet.

Zerk’s property soon began to reappear in the Chicago area. Three men, all between 35 and 40 years of age, were soon arrested. All had Mafia ties along with having various murder and robbery charges against them from other crimes.

Ultimately four people went to prison after Zerk’s testimony. One interesting tidbit is Zerk was able to identify the three assailants via photograph after having only briefly seen them.

Oscar Zerk would marry for the fourth time in August of 1954. He lived the remainder of his life at Dunmovin’ Estate, passing away at age 90 in 1968. His wife, Dorothy, lived there until her death in 1995.

Incidentally, Dunmovin’ Estate was used as the setting for the 2000 movie The Last Great Ride. Sadly, Dunmovin’ Estate fell into disrepair and the house was demolished in 2012.

Without Oscar Zerk, the ease of keeping machinery running may not have been equaled. It is estimated at the time of Zerk’s death in 1968, somewhere around 20 billion of his grease fittings had been produced.

Jason: perfection. Thank you ! Replace “Therefore” at the beginning of your nineteenth paragraph with “Thus,” and I’m sold.

Inquiring minds might wish to know how the manufacturer gets that little ball and spring inside what appears to be a solid brass turning. Not a unique problem, surely—but is there a source available to answer the question ?

My question, too.

Spring and ball are inserted into the fitting, one end of which has already been machined and threaded, through a hole in the end that will accept the grease gun. They are held in place by a rod and the end of the fitting is then pressure formed, the hole thus being reduced in size to the diameter of the rod, which is then withdrawn.

Could it be the other way around and assembly is via the threaded end?

Thanks Jason for educating us about a man I didn’t even know existed. If you had told me that ZERK – a name I’ve been familiar with for probably 50 years – was an acronym fo “Zero Effort Relubrication Kit” I would have believed you. And what a life, from Moravia to the Austrian Army to Kenosha, a large collection of jewelry … and a 1951 Chevy!

I can recall my Dad teaching me how to lube the Zerk fittings on the steering spindles on our John Deer 112 garden tractor. Later at college when I was working in the physical plant while attending classes the grounds supervisor would have us use the Zerk fittings to lube the spindles for the mower decks on our tractors.

Never did the thought enter my head “I’ll bet Zerk was somebody’s name.”

It sure is hahaha.

Thank you for enlightening me on the life and times of Mr. Zerk. I pay tribute to his invention on a regular basis.

and his family had possessed a degree of prominence since the days of the Roman Empire.

I think you mean the Holy Roman Empire, which was created in the Middle Ages, lasted until 1806 and encompassed Austria and other areas of Central and Western Europe. It was a different animal from the Roman Empire.

I will update that.

Mr. Zerk was definitely an intriguing man. Another source provided some information I could not corroborate saying Zerk also invented a type of wheel for use with wheel covers, helping do away with the old spoked wheels.

Holy Zerks, Batman! All of the grease fittings on my 2008 Chevrolet have disappeared! What would Mr. Zerk have to say about that?

Since 1959 the automotive industry has been working at removing Herr Zerks invention from their products making chassis lubrication a non event the Triumph Herald was the first to achieve this by using nylon bushings everywhere, Fascinating look at an invention Ive given little thought to just pumpimg grease into fittings regularly as required on various bits of machinery over the years because thats what you do.

The Herald did have grease nipples on the universal joints, and also on the bronze trunnions at the bottom of the front suspension uprights – and for these you had to remove the grease from your grease gun and fill it with gear oil !

I credit the serviceable (via zerk fittings) balljoints and bushings with the longevity of the all-original front end of my Suburban at 292k miles. Incredible stuff. It was one of the first jobs I did on the truck after buying it, hitting all 11 of them up with a grease gun.

Nice work Jason!

A fascinating read! I have spent many an hour gaining familiarity with Mr. Zerk’s brainchild but never knew it. There are probably few inventions from that early in the development of the automobile that have gone for so long with so little updates to their basic construction.

What a completely awesome piece!

It’s always grated my ear when somebody will say or write “zert fitting”, but as he was Austrian it would have been more like “Tsairk”, so I guess I don’t have as much ice to stand on as I thought when griping about pronunciation.

Zhat iz a great story, senk you!

I miss watching ball joint boots plump up and universal joints exude grease. Greasing a car was a satisfying job. Not as satisfying as not having to grease it at all, but still it was a good feeling.

You need to own a Ford Model A – As I recall there were something like 30 grease fittings on that car, each supposedly requiring personal attention every 1000 miles. You will get your fill of greasing mighty quickly. 🙂

I recently replaced the sway bar end links on my ’04 Toyota and the aftermarket links came with to Zerks on either end. It took me two hours to find my dammed grease gun that was hiding out in the shed. I hadn’t used it in at least ten years after I sold my ’87 F-250, or maybe on my old Greenbrier sold 20 years ago…I forget. It still worked with a pretty full cartridge of moly.

Interesting story, and what a great name!

Thanks for more enlightenment Jason!

Wow – fascinating story about someone I’d never heard of. I’ve heard the term Zerk and Zerk Gun before, but always assumed it was slang.

And somehow I never knew that personal coffee grinder didn’t exist in the 1950s. Too bad about the Dunmovin estate having been demolished; as I was reading this I was hoping it was preserved as a museum of his inventions and (remaining) collection.

Incidentally, is it just me, or did Mr. Zerk bear more than a passing resemblance to Harry Truman?

He does indeed resemble Truman.

One item about Zerk’s collection I omitted – none of it was insured at the time of the theft. He was able to recover the bulk of the stolen items.

He does look a lot like like Give ’em hell Harry.

A very good story, a great man.

Now we have lube for life. When it needs lube, its life is over.

Great essay! Thanks. After knowing of Zerk fittings all my life, I learned why they are “bearing” than name.

I wonder if the featured fitting meets SAE or Zerk specs for shape? It looks a bit off.

There are some combinations of coupler and fitting, though both are spec, when connected are almost impossible to separate.

Ditto to all the above praise, Mr S. And quite the tale.

As it happens, before encountering CC, I’d never heard the term, as they were universally called grease nipples in Oz.

Ofcourse, many might have assumed you were writing a Dr Suess piece if your title had been “The 20 Billion Nipples of Mr Zerk”.

I was an adult before having heard “Zerk fittings”. Like you, these items had either been called “grease nipples” or “grease fittings”.

Your suggested title is infinitely better than what I created. 🙂

Well, I just learnt something new. Thank you!

Excellent and informative piece Jason. As a young man I worked an oil change rack for a brief period and greased many a zerk. Greasing was the least enjoyable part of that job. I have typically preferred my front end components to have Zerks and have had good luck with long lasting parts. This is likely because I ensured the parts were regularly greased. From my experience in the service industry, they often get skipped or poorly greased by techs in shops. However, I have to admit that my modern vehicles sans grease fittings are much easier to service. My truck has over 150k miles on it original sealed front end components and it shows no signs of wear.

Ford used Zerk-less ball joints in the E series vans of the 90s (and probably before and after). Those things had a notoriously short life. On my own van the factory units were shot at under 40k miles and were replaced under either full or partial warranty (uppers and lowers at different time) with OEM Ford parts. Then those miraculously failed at right around the same mileage interval. At which point I paid out-of-pocket for the third set which was equipped with Zerk fittings and which lasted for the rest of the life of the vehicle.

This was the car that hardened my attitude about “lifetime lubricated” parts. Yes, they are lifetime lubricated, but they don’t say how long the lifetime is.

True many sealed components were junk like the ones on your Ford. This is why I used to prefer the greasable components. However, a sealed component designed properly with quality construction, seem to last very long, certainly comparable to the older greasable parts. I am sure the front ends in your Honda and Kia have held up fine, just like my truck and all our other modern cars have.

Some sealed components in industrial applications are unbelievably long lived.

IE forklift tie-rod ends that are constantly cycling under heavy load. Some were difficult to access to grease and so often were skipped, leading to early failures. Sealed units last the life of the truck.

Early Ford medium/heavy trucks seemed to do well with sealed steering components. …and that was 1960s tech.

You’re one of CC’s elite storytellers, Jason…..I join in the praise and thanks for the story. Really, before I found the oddball news item (Kenosha burglary), I had no idea “Zerk” was a name = product think. Go figure!

CC Effect, Zerk edition: I own a small cartridge grease gun because my snowblower has a couple Zerk fittings on the impeller’s axle. Yesterday was in fact the day I mowed the lawn one more time, then changed lawnmower’s oil and exchanged its place in the garage with the snowblower, which I then readied for winter duty (including the grease job). How cool!

As a child I remember being driven past Dunmovin (Cooper / Zerk) Estate and admiring the big house set back from Cooper Rd and the pond that was in front to the left of the house.

You should submit his bio to Wikipedia.