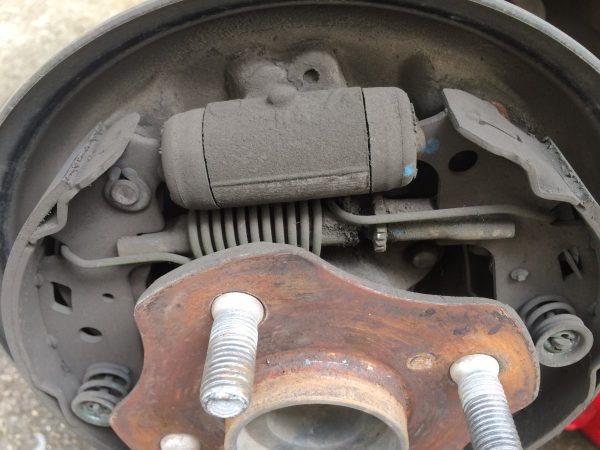

Putting them back together. Pain in the butt. Every manufacturer’s seem to go back together a little different. And given how absurdly easy it is to change most disc brake pads (15 minutes), I’m spoiled. Now how does this go back together….?

I didn’t take these pictures before I took the rear brakes on my xB apart for a post; it was so that I had a reference to help me put them back together. The springs seem to always be different, and since rear drum brakes wear so slowly, it’s not like this is a common job. The xB has some 95k miles on it, and this is the first set of rear shoes it’s needed.

When you do this once only every quite a few years, at least for me I could use a bit of help. Actually, what I could really use are some tools to help expand the springs. Trying to put them back with pliers means that inevitably the pliers jaws reach the limit of their grip just as the spring is a nano-millimeter short of its hole. And it happens repeatedly.

But at least I was semi-smart this time and used my smartphone camera to help me with the reassembly. That helped.

I’m just not a naturally gifted mechanic. I’m a jack of all trades, so I can usually git ‘er done, by hook or by crook, but I’m not going to be shooting any YouTube how-to videos. Which of course I forgot to consider as an aid. Actually, it really wasn’t all that hard except for the fiddliness of the final assembly. It’s the sequencing that’s key, and of course the right tools. Next time….sure.

Invest in some proper brake plyers and buy a spring kit for your application. No wrestling old Springs, you just cut them off.

I like that you rarely have to mess with rear drum brakes, so it’s a chore but a really infrequent one.

The camera trick sure helps a lot, as does jacking up both sides of the vehicle so you can compare the other side when putting it back together.

That reminds me, I should adjust my VW beetle brakes. Lack of self adjusting mechanism makes those shoes easy to reassemble.

Any yes I should have bought the drum brake tool 35 years ago, but I’ve gotten so far without it…

Forgot to mention, when I get a difficult spring I make a loop of baling wire and tie it with a square knot. Then you can slip that over the hooked end of the spring and get a good grip on it. Once the spring is on you can cut the wire and pull it out.

Great idea. I’ll keep this in mind.

The horror that were the rear disk brakes on my ’88 Regal GS made me love rear drum brakes. Hated working on those things.

Thank you! I can do a disc brake job in no time, with my eyes practically closed. Drums? I’ll unashamedly admit that I’ve never even attempted that task; it’s inexpensive enough that I’ve let a shop do it on the few occasions when it’s needed to be done.

We’ve gotten into a few passionate discussions on this site over the fact that drum brakes – in proper working order – are as perfectly acceptable as their disc counterparts. But as a shadetree mechanic, give me discs!

Amen!. Front brakes on the Taurus- 1/2 hour, max. Rear brakes? Three of us, a case of beer, and a weekend. I guess we could have done it sooner, but you get the idea. Upside is it was 12 yrs and 160K miles to get to that point.

Seeing your pictures bought back some memories. I was a mechanic for Sears Automotive from 1981 through 2014. I’ve done my share of drums brakes. Disc brakes on front eliminated the problem of unequal adjusted front brake shoes that caused vehicle to pull when applying brakes. Rear disc brakes, like on Bob’s 88 Regal GS with actuators, caused some problems with depressing the piston without the proper tools. My new Pacifica has electric emergency brakes. On this setup, I can go through my radio and retract the pistons to install rear disc pads.

Wait, what now? I have a Pacifica also! Explain this wizardry of doing something through the radio to retract the Pistons?!?!

Expression, nothing to do with radio

The large drum brakes on my old ’70 C10 weren’t so bad to work on, but the tiny rear drum brakes on my MK2 Jetta are a genuine pain in the ass. I always do one side at a time for reference, but always manage to remove some skin trying to maneuver those tiny, slippery and really stiff springs into their cramped location. And on the VW you need 3 hands and 2 sets of vice grips to attach the handbrake cable to the brake shoe lever. Sadly, another 150k miles has passed and it’s in need of another set of shoes.

Not looking forward to this!

YouTube really can be helpful for stuff like this, but I’ve been frustrated on more than one occasion watching several videos by different posters on the same subject and finding discrepancies or contradictory advice. I’m no mechanic either, but I’m either brave enough or dumb enough to take on most projects that don’t require highly specialized tools or equipment.

My last YouTube assisted project was the replacement of the cooling fan assembly on the 300M last year, which involved a completely ridiculous amount of disassembly before extricating the part to replace it. I stumbled upon a great video that made the job quite easy. Of course the next time I have to play shade-tree mechanic I’ll have to start the search for tutorials all over again because I neglected to save the name or subscribe to the channel of the guy whose excellent post helped me out on that occasion. So that’s my 2 cents: If you find a good resource for guidance….bookmark that shit.

Here’s the tools you need. $12.99 at Harbor Freight. Top one is the spring tool, middle one is the adjuster tool, and the bottom one helps attach the retaining springs.

Worth every penny. I kick myself every time I use mine, for not having bought a set decades ago.

Yep, the last time I worked on drum brakes was on my 1965 Pontiac, circa 1972. I still have a scar on my palm from where the retainer spring, that wasn’t properly seated, slipped out of the pliers and took a bite out of me. In retrospect I’m just glad it hit my hand and not my face.

Like you, I too have a scar on the back of my hand trying to change drum brakes as a youth with only a set of pliers and screw driver.

Since then, I will but any tool necessary that will save me time and my skin when doing any home or auto repair????

Only the retaining tool would work on Paul’s application. That spring tool is for the old Bendix and Delco-Moraine brakes and the spoon is likely too wide to fit through the access hole and too wide the other way to fit in the teeth very well.

Brake pliers, spoon & spring tool. If anyone wants a set, I’ve got some left over from my mechanic years – about 1/2 century ago. Can have free for postage cost only. I’ll never use ’em again.

If interested, I may have a left over wheel cylinder hone too. I’ll have to check the toolbox.

Well there are different systems of disk brakes, some of which are easier to work on than the other, and the same goes to drums as well.

E.g. changing the pads in Lucas fixed caliper two-piston disk brakes can turn into the stuff of nightmares if at least one of the pistons is at least slightly stuck in the “out” position (the pads just won’t go into the caliper unless you literally hammer them down, which is – no need to mention – not a good practice; good luck with breaking loose the stuck piston without damaging anything, yourself included).

Drum breaks on most cars seem to be like those shown in this article, that is, of the “floating shoes” design, and changing the shoes may be pretty challenging. However, I’ve never had any problems with Volga and UAZ rear drum brakes, which are as far as I know of the old, pre-War Lockheed design, like on a pre-War Plymouth (my 2008 UAZ still had the same design of the rear bakes that was used on the Pobyeda back in 1946 !).

In this design, the shoes are pivoting on eccentric anchor bolts and are held in place by spring-loaded shoe retainers, and putting everything back together is an absolutely straightforward job. No need to hold the whole assembly in you hands, ensuring that it doesn’t fall apart as you try to install it in place while it is still in one piece. Just put the shoes with their anchor bolts into their places, one by one, screw the nuts on the anchor bolts, fix the shoes with the retainers and connect them by the single return spring. Job done. The automatic adjusters are inside the hydraulic cylinders, so no need to worry about them. The parking brake linkage is not there as well, because the UAZ and many of the Volga models have the parking brake mounted on the transmission output shaft.

Still takes more time than to change the pads on most disk brakes, if you include the time needed for the adjustment of the shoes using the eccentric bolts. But the only tricky thing in the whole job is to remove and then install the stiff return spring, really (especially if the spring is brand new; old springs tend to be less stiff and are easier to work with).

Front brakes (wherever they are not disk brakes) are of a more complex, two-leading shoe design, but the shoes also pivot on anchor bolts and the assembly/disassembly is pretty straightforward, too.

What I can attest to, is that the drum brakes on old cars invariably work much more reliably and are much easier to restore than any disk brakes whatsoever.

Cars still have drum breaks? ?

No, but they do still have drum brakes.

Me too. I hate working on drums. Discs are so much better all around.

The worst I ever did involved a 1957 or so Jaguar MK I. Jaguar never mixed disc and drum. When they changed; it was to 4 wheel discs. The Mark I had 4 wheel drums, and the rears were so worn that some of the hardware had broken, or detached. They did not want to come apart, and the adjustors were inoperative, When they finally came apart, parts were made of unobtanium, and reassembly required imagination.

I always preferred disc brakes, and back then, we did our own caliper rebuilding. Now you order loaded rebuilt calipers and the job is much easier.

I still have scars on my hand from a flying brake shoe spring from auto shop in 1996. Good thing I was wearing goggles.

Wait a second. I would assume your 66 Ford pickup has drum brakes on all four like mine. So that means some familiarity with them. I have 20 drum brakes wheels scattered among my cars with two of them being all drum. Consequently I have done them many times and those brake tools are indispensable. They are all relatively easy to do except for the fact that the Focus requires you to remove four bolts on the backing plate side to remove the drum.

Interestingly I have yet to do the Focus with 160,000 miles and all original brake material, front and back, that is only 60% worn.

Well, the last time I did the brakes on it was about 15 years ago. 🙂 I only put on about 1500 or so miles per year on it, just for hauling stuff.

You must go thru a lot of sneakers……

My 2006 Xb gets new front pads roughly every 50K but went 260K before needing new rear brakes (but then it definitely needed them).

Despite a recent comment in which it may have sounded like I was wishing for the days of yore, I really don’t. And drum brakes are a distinct factor in that sentiment.

I’ve dealt with drum brakes just enough to know I’m not overly fond of them. Having replaced them on the Galaxie and on the rear of our long departed ’01 Taurus (and likely something else along the way), they make one really appreciate disc brakes. That said, I have seen more variation of the theme with disc brakes, but not anything as daunting in appearance as drum brakes

I dunno Paul, based on the used shoes in your pictures, it looks like you could have gotten another 25 k or so out of them….

Yeah, but that was the good side. The other side was getting might thin. The adjusters must not have been working in concert or something like thta.

You’re lucky! No rust!

Easy to do on my lincoln mark vi. It’s just as easy to use polliers and vice grips as the correct tools

Nobody has worked on later GM truck rear discs yet? Absolute junk, flimsy sheet metal parking brake shoe inside that requires disc removal to adjust. Even on the one ton jobs except that the design is so bad that the calipers can’t be removed to replace the pads. One has to remove the caliper bracket with the caliper for a simple pad change and juggling both to reassemble is no fun. Removing the disc to adjust the parking brake shoe involves removing the axles and pulling the hub/disc assembly as the disc is not removable on the vehicle. A time waster and you end up replacing hub seals to make an adjustment that should be simple. Absolute garbage, poor design like this is a contributor to why GM failed and should have been left for dead. I can appreciate a well designed disc, the solid mount two piston ATE used on a lot of Euro stuff works well and is super easy to replace pads on. Disc or drum, I really don’t care as long as it is serviceable.

And then there are the Chrysler Lockheed Center Plane Brakes fitted to Chrysler Corp vehicles up until the 1960s. These are the front brakes on my 1955 Plymouth. Two wheel cylinders per side, adjustments have to be made using a Miller or Aamco brake gauge that hasn’t been made in 50 years. I’m making do with a dial indicator and a big ass socket. This is my weekend project, and once I get these brakes sorted, this curbside classic will be back on the road after a 20 year hiatus.

Twin leading shoes, cool !

Full marks for improvisation

My Peugeot 404 wagon had big, wide twin leading shoe front brakes. I loved those brakes; they were so strong but so gentle and easy to dose. No power assist needed. Seriously, they were my favorite brakes ever. Much better than the rather mediocre discs on the sedan.

Two cylinders seems a nice idea-fewer springs to wrestle with, perhaps stronger braking even without power assist, and also the potential for more even shoe wear.

I wonder why it didn’t catch on.

I’m sure it is more expensive than the single leading shoe version that most manufacturers used.

Twin leading shoe brakes were common on British cars my Hillman had them and they worked reall well but still fade with repeated applications on steep mountain roads I replaced them with discs some time ago and even unboosted those work better, and much easier to replace the pads no springs to wrestle with or go pinging off into the distance when your pliers slip.

Didn’t those Chryslers have lug nuts that loosened cw on the passenger side and ccw on the drivers? Or something like that!

Yes. The left hand side had an embossed “L” on the head of each stud.

Even though I watched my father change many a set of drum brakes, the apparent complexity gave me an irrational fear of them for many years. Dad could do it without even using the other side as a reference, and he took the old-school approach of rebuilding the wheel and master cylinders.

The right tools, in my experience, as well as using the other side as a reference, make all the difference. I also install new cylinders and a complete hardware kit. My F100s have drums all around, all of which I have replaced, so I am now fairly confident in my ability to get the job done properly and quickly.

The time interval between changes, as Paul remarked, is significant with a vehicle that doesn’t accrue many miles, and my modern cars have discs all around, so I will spend a bit of time walking back and forth, scratching my head, marveling at the apparent complexity of the mechanism when I next have to change the brakes on the old trucks.

Replacing drum brakes never fails to renew my awe of and respect for the people who figured out how to build these Rube Goldbergian mechanisms. My brain hurts a little when I allow myself to dwell on it. Speaking of dwell, I have similar experiences with mechanical ignition systems.

This topic, like many on here, brought back memories of my father. His tools, many of which now inhabit my boxes, allow me to include him in repair jobs and keep his memory alive.

I have a complete set of brake drum tools, even a brake cylinder hone, that has been unused for at least 35 years. I could bring it up to Eugene next week. But … my new Tacoma has rear drums and I might need the tools some day. When our ‘93 Corollla had about 75K miles on it I needed to replace the front pads, and picked up some rear linings at the same time. The rears looked like new, so I tossed the shoes in my parts box. Before selling the car at around 95K miles, like your xB, I checked the linings again. No significant wear; I gave the replacement linings to the buyer. I don’t really understand how drums have lasted so long … I’m sure disc brakes must be cheaper, with fewer parts and simpler assembly. Even the old argument that “the tooling is paid for” seems questionable; I’d think the tooling for these small Toyota rear drums would have worn out decades ago.

Same here – I have all the tools but have not used them since the 80s. I have either paid the mechanic or followed the Jim Klein school of auto repair (dump the car).

Now you have me in a mood to do some brakes. I wonder if it is time on my Fit?

I believe that rear disc brakes are more expensive to manufacture than rear drum brakes because of the parking brake. Rear disc brakes are composed of two separate braking systems: the hydraulic disc brake used to stop the vehicle, and the parking brake, which is a cable-actuated drum brake. The drum and its associated hardware is inside the rotor, which gives the rear rotors a more accentuated hat-like appearance than the front rotors.

Rear drum brakes, on the other hand, are simpler, and likely less expensive to build, because the same set of parts performs both functions. The parking brake cable is attached to one of the brake shoes that is used to stop the car.

Not are rear drum brakes have the parking brake in the hat set up. In fact that is a more modern development as they were actually cheaper and way less problematic that the calipers that incorporated the parking brake.

The problem I’ve seen become more frequent with the drum in rotor parking breaks is that they do not wear, unless someone drives with the parking break on. At first this seems like a great thing, they will last the life of the car. However the fact is that on bonded shoes the glue eventually fails. That leaves you with one lining that is now floating in the drum which will wedge itself between the drum and the other shoe that still has its friction material which locks up the wheel. Last fall it happened to my Daughter’s car as she tried to pull out of the parking space to head back to school one Sunday evening. Thankfully it did happen here at home so we just had to transfer her stuff into my wife’s car and sent her off. Monday morning I found exactly what I expected one floating lining in the one side that was acting up.

That said I’ll take the drum in rotor parking brake system any day of the week.

Which reminds me that I should probably do the brake shoes on my F250 when I do the rear pads which are due soon.

Nasty, NASTY things which I’d quite forgotten as yet another reason as to why I hate drums. The last rebuild I did was on my 404 twin-leading shoe set-up. Cuts, bruises, millimetre falling-shorts, and all to have brakes that were only ever mediocre. They pulled up ok – nothing like what Paul describes – but they also did as every drum brake has ever done; wear unevenly, eventually pull to one side or other, lock without any pattern in hard stops (one side, one back, one front etc), rumble and graunch at highway speeds, get too hot and fade, lock on and bloody well weep or outright leak. Alright, I’m adding a few experiences across some other cars there, but dammit, if it’s not a disc, it’s not a brake! It’s just a Combined Slowing Suggestion Mechansim and Injury-Maker.

I too have a permanent mark, back of the knuckle where the pliers slipped off the spring with half a bee’s dick to go and my hand ricocheted into the inside of the mudguard lip.

Bah, even just looking at the photos makes my blood pressure rise. Only thing close to those things in motoring faff-about bash your head/knuckles/ass crappiness is exhaust systems…

Were those on a 404 early sedan or wagon? The wagon had subsatnatially bigger/wider front drums, and the ones on my wagon were a dream. And putting them on was considerably easier specifically because the twin shoes could each be mounted separately, which made it quite easy, actually.

Sounds like they didn’t exactly agree with you, though.

It was a very early sedan. You’ve jogged a memory that the assembly problems were indeed with the single-shoe rears. In truth, I had had to replace most of the hydraulics, and I suspect that I got something wrong in the assembly of all that (maybe a crimped line?) Being a single-circuit system, any point at which something wasn’t flowing properly would affect all. But having said that, looking on threads in Aus now, no-one raves about the drums (it’s all about ways of putting discs in). I know that in Europe, the injected cars had a super-powerful booster and the wide drums. Aus 404’s were local assembly, so likely mix n’ match local brake components weren’t up to the imported brakes the US got. Might even be a RHD issue, rather like the awful brakes on RHD Mk1 Golfs which used (effectively) a torsion bar to operate LHD components!

Still think drums are an evil invention of the AMA, though.

Bah! Humbug! Fancy store bought tools? After a good few years away from drums I was dragged back into them when I bought my 4 wheel drum Skylark. Did a front disc conversion, so that solved half the problem.

The ‘lark rear drums are the Duo-Servo design. Very familiar to me from Holdens.

I was taught to grab the shoe return springs with sidecutters (wire cutters to you Nth Americans, I think), and put your shoulder into it. The other tip was to always cover the wheel studs with a rag, in case the sidecutters slipped. Been doing drums that way since 1978. Works for me. And thanks for the reminder, I need to adjust said drums for the track cruise at the All American Day tomorrow.

I also still have a full set of drum brake tools, but none of them are of any use for assembling the Plymouth brakes, which is a good thing. The shoes bolt to the backing plate and slide under the hold down spring which is part of the backing plate. The return springs are easily installed using a thin screwdriver for leverage and guidance. Much easier than trying to pre assemble a Bendix style shoe set, set it in place and hope that it will hang there long enough to get the hold down pins and springs mounted. Even with the right tools, installing Bendix brakes is a pain.

The return springs are easily installed using a thin screwdriver for leverage and guidance.

Yup, that’s the way my grandfather did it on his Plymouth. He had both those springs in place in maybe 3-4 seconds.

My 89 Bonneville had a different spring set up in the rear brakes. If you tried to lodge/dislodge the spring without the special tool (shown here), you would spend much more time and effort than you would with typical drum brakes.

Drum brakes were a snap for my grandfather. He had worked as a mechanic for 50 years, so he had the process down pat. Watched him replace the brakes on a 66 Plymouth one day. Only specialized tool he used was to back off the self-adjusters, and he had made that tool himself. I think he did use a pair of pliers to pull the springs off, but used a big screwdriver to put the springs back on.

My boss at the last place I worked cursed VW rear discs tho. He had done plenty of discs, but, try as he might, he couldn’t get the pistons to go back in the calipers on the rears on his son’s Jetta. Asked a guy he knew. VW rear discs use a screw type self-adjuster. To retract the pistons, you have to turn them to screw them back into the caliper.

I don’t do drum brakes anymore. I have 2 classics that came with drums on the front; one has already been converted to front discs and I’ll do the other when I get the chance. Rear brakes are done so infrequently that when it is time, my local shop on the corner with a competent mechanic does them for me for around $100. Money well spent saving myself time and frustration while I’m supporting the local economy

As has been mentioned some techs have amazingly simplified methods for dealing with brake assembly. With most drum brake designs there are techniques to pre-assemble the shoes and most of the “fumbling” parts on the bench and then to “hang” the complete assembly to the anchor, leaving just the easy-to-hook return springs and hold-downs to install.

The problem for an infrequent flyer is a lack of knowledge and practice.

Looking at the pictured brake I wonder if the two shoes, adjuster, its spring and the parking brake lever couldn’t be pre-made in the wide open, and then the shoes “hinged” together at the bottom to get all that behind the hub flange and mated to the wheel cylinder in one easy move?

But again, except in a brake shop environment the learning curve wouldn’t justify the payback.

I used to be able to do drum brakes in my sleep, years ago. Haven’t wrenched since like 2001 so I hadn’t dealt with them in a long while.

then one of the linings fell off of my Ranger’s parking brake shoes. Mine has rear discs, and uses the “drum-in-hat” setup with a tiny drum brake inside the rotor. Lemme tell you, trying to get in there and get the pushrods inserted (under spring compression) on a brake which is barely bigger than the axle flange in front of it is a good way to invent new curse words.

Of course it is too late now but no spring tool is required or desired for this system. It is all done with fingers other than the hold down springs in some cases.

The basic steps.

1 attach the parking brake lever to the shoe

2 hook top spring into shoe with p brake lever.

3 hook top spring into other shoe

4 bring bottom ends of shoes together so the adjuster will slip into place.

5 open the shoes to almost normal position and fit them over the wheel cylinder

6 put the retaining spring on the shoe with the p brake and place the bottom of that shoe in the anchor.

7 place the lower spring on both shoes but with the un-retained shoe on top of the anchor.

8 pull the loose shoe out so it will clear the anchor. Sometimes you need to use a screw driver as a pry tool but many can be done by hand.

9 put other retaining spring on

10 shimmy the shoes into the proper places.

I remember drawing a diagram of the springs on the box the new shoes came in (way before those new-fangled smart phones)

In 1987 I attempted a refurb of the 4 wheel drum brakes on my ’75 Datsun pickup. And I just finished!