In November 1980, truck maker DAF introduced their last conventional truck and tractor model, known as the N2800-series. It was specifically developed and built for the African and Middle Eastern heavy truck market.

In practice, that meant the N2800 was perfectly capable of dealing with harsh driving and climate conditions, all day long. It was rugged, uncomplicated, durable and overloading-proof.

The N2800 conventional replaced the venerable ATE 2400 DK cabover. An old soldier, as its design dates way back to 1957, when DAF introduced their first heavy truck and tractor model, called the 2000 DO-series (and what a wonderful picture this is!).

See? Same job, same circumstances.

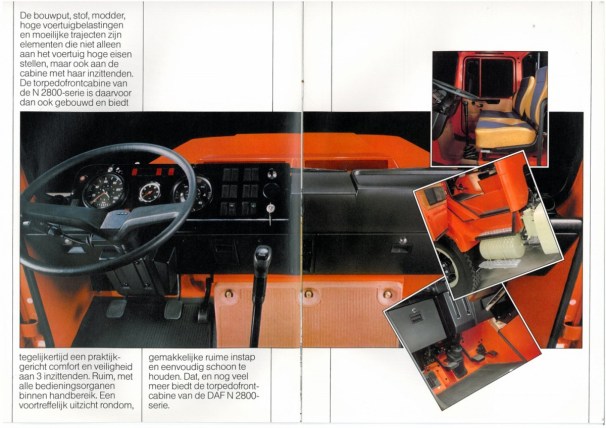

The cab for the N2800 was sourced from Magirus-Deutz. The Germans used it on their air-cooled Eckhauber, another tough cookie for sure.

Seats for three in this clean-with-a-hose interior. The transmission is a ZF 16-speed (double H shifting pattern).

Just like all other big DAFs from 1968 to 1997, the N2800 was powered by an 11.6 liter inline-six. The 1160-series of engines was DAF’s evolution of the 11.1 liter Leyland 680 diesel.

The versions available in the N2800 were the naturally aspirated DKA 1160 (230 hp) and the turbocharged & intercooled DKS 1160 (310 hp).

Both the truck and the tractor chassis were only offered with a 6×4 drivetrain, hub reduction came with the package. The tractor was designated NTT2800, the truck chassis NAT2800.

DAF rated their 2699 T 6×4 tandem at a total axle load of 26,000 kg (57,320 lbs). Overloading-proof, as mentioned.

Almost all NAT2800 chassis worked as dump trucks or concrete mixer trucks. The tractor units were often used in the logging and heavy-haulage business.

Over the past years, I caught a few of these heavy-duty rides. Like the 1982 Paris-Dakar rally raid truck, back then the winner of the > 10 metric tons class.

A 1985 heavy-haulage tractor.

This 1981 recovery truck.

And an NTT2800 in chains.

These conventionals were built till the late eighties. Nowadays they’re considered as cult classics among DAF truck enthusiasts. Chances of DAF ever introducing an all-new conventional? Slim to none, I’d say.

Brochure pictures courtesy of public.fotki.com

Handsome truck! It’s certainly nothing I’d see in the States, but it looks like a cross between a Ford and an International of the time.

Did you say International? Meet the DAF N2500 from the early seventies. The second gen of a “DAF” conventional.

Under its hood a DAF diesel though. An extremely rare bird, I’ve read only 20 or so were sold.

Indeed, a very handsome truck! The rear suspension looks like each axle is attached to the frame by four links, and suspended by leaf springs. I don’t think I have ever seen this. it would have allowed for very good axle control, maybe a better ride as the leaves only had to absorb bumps and not also provide for location control, but would have added complexity,.

Yes, there are 8 “reaction arms” (translated from Dutch, don’t know if that’s correct in English) in total. You can see them in orange in one of the brochure pictures of the yellow N2800.

DAF trucks and tractors from those days were known for their stable ride. Tanker and bulk haulers (high center of gravity when loaded!) loved them for that reason.

The “reaction arms” in the States are typically called “torque arms” or “torque rods” or similar.

Shortened from “torque reaction arm” probably.

Ultimately they are what transmit braking or driving forces to the chassis.

Right, thanks!

Planetary gear hub reduction! I did not know that this was done like this, and that these had it. I wonder what the advantage was over just reducing the gearing in the final drive?

Can’t tell, but I do know this has always been the standard for heavy-duty trucking here (on-/off-road, logging, heavy haulage). As far as I know, all truck makers did and do it like this.

A bit of Googling shows that is the case, especially in Europe, but also on serious HD trucks here too, at least in some cases. Makes lots of sense, as it allows a smaller pinion gear in the rear axle and allows the axle shafts to be lighter, and reduces chances of breaking them, as the torque is now lessened on them.

Please correct me if I´m wrong but if you have a reduction at the hubs then the shafts spin at higher rpm which would call for a larger pinion gear at the diff.

Jorge, higher loads typically will require a larger (stronger) pinion-shaft, etc.

Tooth-count (speed ratio) is independent of load capacity – to a point.

At a certain point in load capacity, approx. 50,000 lbs US, conventional final-drives, axle-shafts and hubs must become massive to handle rated torque loads. Moving final gearing to the hub lightens the load on “up stream” components, allowing for lighter and more compact components.

Nevermind, looks like the answer arrived while I was posting.

I (we) can certainly appreciate some extra information.

Drive train weakness dictates all sorts of things that T610 I drove was limited to 1950 ftlbs of torque because thats all a Eaton fuller 18 speed ultramatic can cope with reliably the rig was stickered for 58 tonnes doing wine 54 on milk and would get well down in the gears climbing hills, 615 hp and 1950ftlbs will break something eventually

Hub reduction is the norm here on anything with a 6×4, 8×4 or 10×4 drivetrain (let alone 4×4, 6×6, 8×8, etc.). Just another example, the 2016 DAF CF 8×4 concrete mixer truck below, legal maximum GVM 85,980 lbs.

Is that about a 9 metre bowl on the mixer, concrete is bloody heavy stuff and its liquid while being trucked, makes those things quite tricky to drive, 7 metres was the biggest we had on 8 wheelers like that back when I did concrete.

Standard 8×4 mixer trucks (with the factory axle spacing at the rear) haul 9 to 10 m³ of concrete.

With an aftermarket conversion (rear tandem with more axle spacing and a steering last axle) that can be increased to 12 m³, see DAF CF below, same owner as the factory CF above.

10×4 mixer trucks are also quite common in my country, 15 m³ drum capacity.

6×4 mixer trucks (six-wheelers) have become something of the past. Too small/not efficient. The bigger the drum, the less trips to the construction site, as simple as that.

Perhaps with some then popular quad rectangular headlights, and a tidier grille, it would have been one of the more stylish cabs from the era. A clean design.

Nice work!

That recovery truck is still in use!

DAF rear drive hubs still resemble that on some recent models, but thats a cab Ive never seen, not a bad looking truck if you really must have a conventional I prefer cabovers but thats what I usually drive and prefer for visibility and manuverability, The guy who fits a Japanese truck chassis with an American engine and a European cab and cab suspension will be on a winner with an all rounder, nobody has done it yet. They all have strengths and weaknesses and DAFs are pretty good but suffer from poor drive traction and turning circle, the MX engines are great.

Who else one wonders if there wasn’t an inspiring Ford L parked on the street when the DAF cab was on the drawing board?

As mentioned, the cab came straight from Magirus-Deutz. The Germans’ last gen of the Eckhauber was introduced around the same time as the L-series.

It was already a decade old when DAF started the production of the N2800.

Well we have a heavy tow truck version and I do like the truck a lot. It’s a beast.