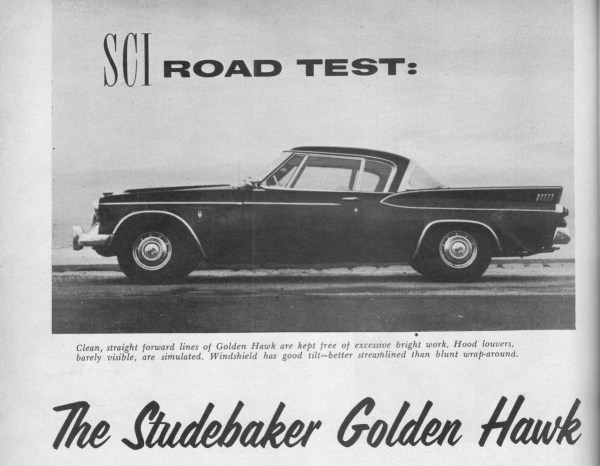

In their Sports Car Directory, SCI included a few select “American Gran Turismos”. It would a couple more years before Studebaker’s Hawk Gran Turismo appeared, but the 1957 Golden Hawk certainly made the cut. And it acquitted itself very well indeed, with acceleration numbers almost identical to those of the mighty 300C, although with a manual transmission and a very steep rear axle ratio. Given that the 300C cost 65% more ($4929 vs $2925), that made the Golden Hawk quite the bargain too. Of course there’s still one more highly qualified competitor yet to come…

The Golden Hawk appeared in 1956 (above) packing a big (and heavy) 352 CID Packard V8 rated at 275 hp under its long hood and new upright grille. Studebaker was making a clear move into the booming sports car market, with family-friendly seating for five. But its dynamics were compromised by its front-heavy bias and it just didn’t quite impress serious drivers unless they were straight line oriented. There was still work to do in making the most of the 1953 coupe chassis.

For 1957, Studebaker ditched the now-discontinued Packard V8 and went the tried-and-proven method for making a smaller engine perform like a bigger one: forced induction. Supercharging is the easy way to “add displacement” when the block won’t accept any more, or to compensate for intrinsic breathing limitations in the head..

Sure enough: the McCulloch supercharger’s boost allows the 289 Studebaker V8 to make the same 275 hp that the Packard V8 made. The magic of forced induction. It’s a single-stage centrifugal variable-ratio belt-driven unit. McCulloch offered kits to adapt them to most American V8s, and Ford also used them on a limited number of 312 Y Block V8s, in order to overcome that engine’s inherent breathing limitations for NASCAR, where it was quickly banned.

The Studebaker V8 also had inherent breathing limitations due to its head design, and supercharging is the handy solution to overcome that. As a point of contrast, Chevy’s deep-breathing 1957 283 V8 made 270 hp with carbs and 283 hp with FI.

SCI was impressed with the improved build quality, which was noticeable in the interior fitments as well as the solid feel of the car overall. As well as its performance, although handling was initially atrocious due to underinflated tires. SCI inflated them above the recommended levels, and it made a significant difference in handling and high speed stability albeit at the cost of a harsher ride.

In case there was any doubt, “it’s no sports car”, and it under-steered heavily, but overall for an American car, SCI was fairly impressed. It was stable at high speed, but the manual steering required lots of effort.

The limited slip “Twin Traction” differential was praised. The GH came with a three-speed manual with overdrive, a popular combination with Studebaker drivers. This allowed a very steep 4.27:1 rear axle ratio, which explains the brisk acceleration (0-60 in 9.3; 0-100 in 23.3; 1/4 mile in 17.3 @86 mph) The 300C’s comparable numbers were: (9.2 sec, 24.7 sec, and 16.9 @84mph). Almost identical, but then the 300C had an automatic and weighed 4775 lbs compared to the GH’s lithe 3550 lbs.

This combination of a high numerical rear end and overdrive three-speed made the best combination until 5 speeds came along, as it essentially had 5 gear ratios to put to work. This was the hot set-up with Tri-Five Chevys too, with even steeper 4.56 gears or so. Wicked acceleration yet quite leisurely highway cruising.

The GH’s complete instrument panel was attractive, but positioned too low, especially at speed. This was a fundamental problem with the Loewy coupes.

My 80+ year-old uncle has one of these now, he’s driven it all around California. My late father and he both had Studebaker Hawks before I was born, and my father later had a GT Hawk, and then an Avanti. You could pick these up rather cheaply in the mid-1960’s after Studebaker finally kicked the bucket, and these cars (for them at least) made a sporty (if a bit eccentric) ride for a young guy on the make. I’ve never ridden in one for one reason or another, but they always talked/talk about them in wistful terms, whereas my mother would say “you guys and your Studebakers!” with some well-earned exasperation.

I for one think they are beautiful, and I think I like the later “Hawk” incarnation just as much as the original Loewy Coupe, though I think the Gran Turismo Hawk probably looks the best out of the three incarnations. It’s too bad that Studebaker couldn’t figure out how to sell these, I guess they made less than 1000.

4,356 ’57 Golden Hawks were built. There were fewer than 1,000 ’58 Golden Hawks built, some 850 /-

I’m wondering-did Studebaker increase the gauge of the metal in the frames of these cars over the original? This review praises the solidity of the body of the car, whereas I recall reading about how “willowy” the original Loewy coupes were.

Very nice description here of what the cars were actually like to drive. I prefer the front end of the original, but this looks well balanced from the side, even with those tail fins and their added “stability.”

Yes, the infamous “Flex-Frame” experiment of ’53 was remedied when the Golden Hawks were built.

Wasn’t this fixed on the ’54 models? What exactly was changed?

The 1955 models received a heavier gauge steel. But the frame design was still just a ladder without an X-member, were still willowy, just not quite so bad as the 1953-’54. The Lark four door station wagons and convertibles finally got frame X-members, they’re what Studebaker guys add to their cars to give them more solidity.

Regarding the comment about the weight of the Packard V-8 in the ’56 Golden Hawks, this is a common mistake. The Packard engine of 352 cubic inch displacement only weighed 65 pounds more than the Studebaker 289 cubic inch V-8.

The Studebaker V-8 was a hefty thing because it was engineered to accept compression ratios as high as 14-1. Studebaker engineers, when developing the engine, were working off of assumptions by the Kettering Institute that engines would soon be developing their power from very high octane fuels and high compression ratios rather then developing their power through displacement. The result was the Studebaker engine had close bore centers which limited its practical displacement increase beyond 289 cubic inches. It had a forged crankshaft, gear driven camshaft and other engineering features designed to make it tough enough to handle the projected compression ratios. The result was one tough engine but it also tipped the scales at a hefty weight.

I didn’t make a mistake. All the Studebakers V8 cars were inherently front-heavy. The Packard V8 only exacerbated that a bit further.

Speaking of mistakes, your explanation as to the Studebaker V8’s excessive weight has essentially been debunked; it’s a common excuse given for the fact that Studebaker’s foundry technology was clearly behind the times.

The Kettering Institute was of course part of GM, and the 1949 Cadillac and Olds V8s were designed with the very same assumption that future compression ratios would increase. Yet they’re significantly lighter on a lbs per displacement basis.

We covered the Studebaker V8 in considerable detail here:

https://www.curbsideclassic.com/automotive-histories/engine-history-the-studebaker-v8/

And all engines back then with the exception of Ford used forged crankshafts and connecting rods.

“And all engines back then with the exception of Ford used forged crankshafts and connecting rods”

After our discussions on this, I saw some mentions that the Stude crank was forged steel (as opposed to forged iron). Was this unusual?

I am not willing to totally discount the “expected higher octanes” story. It is not inconceivable to me that during the design phase they opted to optimize for higher compression rather than larger bore. The bore spacings were wide enough had they designed the cooling passages and head bolt locations differently, they could have gotten a lot more displacement.

I do not disagree that their casting abilities may not have been cutting edge and that goals of ultra high compression and room for bore growth may have been mutually exclusive. But the engine certainly stood up to everything they ever threw at it in terms of compression/supercharging without blowing head gaskets left and right, at the cost of minimal displacement for the heavy weight of the block.

Oh my, this endless non-issue continues….

To my knowledge, there is no such thing as a forged iron crankshaft. If you can find evidence of that, I’d be happy to expand my knowledge. I have only heard about crankshafts forged from steel.

As to cast cranks, there are three options in increasing order of strength:

Cast iron

Nodular cast iron

Cast steel.

To the best of my knowledge, Ford invented the nodular iron crankshaft process, but it was eventually adopted by others, possibly with changes? I’m not an expert.

As has been pointed out repeatedly by other knowledgeable commenters, a well made cast crank can easily exceed all strength requirements for any possible use other than extreme racing situations. cast cranks have been used in drag racers and others.

As to the ability of the Studebaker to keep its heads on with a supercharger, plenty of other engines have proven that too. The Stude V8 has 16 head bolts. The SBC has 17. The SBC was supercharged very commonly in aftermarket, hot rod, racing, boats and other applications. Without ” blowing head gaskets left and right”.

What common American V8 engines in this time frame are you referring to that were “blowing head gaskets left and right”, other than the Olds diesel?

The Ford 312 Y black seemed to do just fine with its supercharger and it had a….cast crankshaft! And was raced at Nascar with that setup.

There’s way too many variables in engines to reduce their qualities down to a few stereotypical elements. I’m not taking anything away from the Stude V8’s strengths, but that doesn’t mean other engines were just as able to withstand similar demands. The implication is that it was somehow significantly more durable. I have not seen any factual evidence that this was the case.

One more thing to keep in mind: Supercharging just compensates for an engines limitations in breathing. But it doesn’t place any more internal stresses on an engine than a naturally aspirated one making the same power.

Meaning: a 275 hp blown Stude 289 is creating less stress on the engine than a NA 283 hp SBC 283. They’re both making similar power, the SBC slightly more, hence roughly the same amount of fuel-air mixture is being drawn in and combusted. The only real difference is that in the case of the SBC, the fuel-air mixture is not getting any additional force other than that of the existing atmospheric pressure due to its better breathing heads. But they’re both burning the same amount of fuel, and creating essentially the exact same amount of internal stresses. No difference.

We’re not talking about dragster-levels of boost here. And FWIW, the SBC was commonly blown to huge levels of boost in drag racing and Bonneville high speed applications and for street use.

On the forging, I was just asking. I don’t have enough knowledge of the forging process to do anything more. Your answer is that it was not unusual, which was all I was looking for.

I am not trying to re-open earlier discussions. My only point was that you seemed to be discounting the idea that one design parameter was to accommodate higher compression ratios to take advantage of improvements in gasoline (which never really came in any volume.) I was just suggesting that given their casting abilities, they may have been in an either/or choice in designing for displacement potential or compression potential (where the big companies may have been able to design for both at once.) If so, they plainly chose compression potential. I’ll bet a decade later there were plenty of people in the company who would have traded a handful of head bolts for another 50 cubic inches.

I am not aware of American V8s with head gasket issues, but only note that the Stude could easily have become one when it eventually got some compression ratios that would have been really wild at the time it was being designed. For an engine that never really got any updates to the blocks or heads and was stuck with its engineering from the dawn of the OHV V8’s era, it held together pretty well when pushed really hard. And, as noted, the cost was falling way behind the competition in displacement.

My only point was that you seemed to be discounting the idea that one design parameter was to accommodate higher compression ratios to take advantage of improvements in gasoline (which never really came in any volume.)

There’s is nothing in my knowledge that suggests an engine needs to be excessively heavy to sustain high compression. The classic Mercedes diesels from the 60s and 70s was essentially the same engine as the gas engine, except that the head had a different combustion chamber as required for diesel operation. It was not at all heavier than typical engines of the times; probably lighter than many others.

I could find many other examples.

My point is this: There is no basis for that assumption, that the Stude V8 was built heavier for that reason. I have come to believe that it’s just become a commonly accepted story (along with its forged crank, etc.) to use as an excuse by Studebaker weight-apologists.

Seriously. I can find zero other reason. If you can, please show me.

I am not disputing that they surely threw a lot of metal at the block for a large margin for error. I only suggest that given its bore centers, it should have been a lot larger displacement, which would have made it less heavy on a per-cubic inch basis.

The thing had 4.5 inch bore centers. The early Cadillac and Chrysler Hemi were only slightly larger at 4.56 and they both got displacement up near 400 cid in the 1950s. The old Chrysler A got to 326 cid on 4.46 bore centers and the Ford Y block got to 312 on a 4.38.

Properly designed, that Stude V8 should have been good for an easy 350 cubic inches which was right in line with what its contemporaries were able to get out of designs of a similar age and bore center. At 350 cid it would have only been “that’s really heavy” instead of “holy shit but that’s heavy”.

So I don’t think we are disagreeing about anything. I just think that they saw an either-or question on compression vs. displacement. (or worse, never even thought about the need for more size) They picked compression and ignored displacement potential. They lost.

So I don’t think we are disagreeing about anything.

Actually we are. We’ve been disagreeing about this point for a very long time know, over and over and over… Because you’re assuming/asserting that excessive weight in the form of more cast iron in the block was necessary (or at least a preferred choice) for the possibility of a future high compression version.

I don’t buy that, as there’s never ever been a good logical reason for making an engine excessively massive for that reason. As I just pointed out, there have been many passenger car diesel engines with 20:1 CR that were otherwise comparable to typical gas engines. And as I said previously, the 1949 Olds and Cadillac V8s were designed too to meet that prediction by Kettering Labs.

What is the rationale that a 14:1 CR needs an excessively massive engine? In Brazil ethanol-only engines have commonly had 12:1 and up to 14:1 CR. No extra measures needed.

Some American gas V8s had 11:1 CR.

Keep in mind that as the CR goes up, so does the efficiency, meaning less of the energy expended in the engine turns to heat. A high CR engine has less need for heat dissipation than a comparable output engine with lower CR.

I’m going to say it for the last time: I am quite convinced that there was/is no logical reason to build a massive engine for high compression. And that the assumption that the Studebaker engineers used future compression increases as a reason. Where is either the proof or supporting logic for that?

As I said before, that’s the story that’s been perpetuated. Read the same thing over and over, and folks believe it. But it has no basis, unless you can show me otherwise.

To just keep repeating what you read in articles written by Studebaker fans or regurgitated by other lazy journalists is not a very convincing argument.

Is you know, I make it a point to take apart “facts” and arguments that have been presented as real facts as a matter of principle (and pleasure). Until someone can show me supporting evidence that the Studebaker V8 was purposely designed to be excessively heavy for that reason, I will assume it was because they were not able to consistently achieve thinner wall casting at their foundry.

From Richard Langworth’s “Studebaker 1946-1966”:

“The only serious criticism ever leveled at the V-8 was that it was too large and heavy for its displacement – a fault that was perhaps only true in the later years., when it was compared to similar displacement units that were much more modern. Otto Klausmeyer says, “The V-8 was not excessively heavy at the time it was designed, but since then great strides were made in foundry techniques to produce a lighter part with the same strength.”

Your figure of a 65 pound weight savings with the Stude V8 – was that for the supercharged version? If not, I would bet that the difference was even less due to the weight of the supercharger and associated hardware.

From numbers published at Carfolio.com, the 56 Golden Hawk (entire car) outweighed the 57 counterpart by 95 pounds. However, the weight of the 56 included the Packard Ultramatic transmission while the 57 was weighed with the 3 spd/OD. I am no expert on transmission weights, but I would suspect that the 56 and 57 were pretty even overall on weight.

I have forgotten the actual numbers, but I once looked up the bore centering on the Stude V8, and it was on par with a lot of larger displacement engines. I think the problem was the placement of water jackets and head bolts which put a lot of that space between cylinders off limits. There were reports at the end of a redesigned block casting that got displacement up to around 340 cid.

I forgot to mention that about the bore centers: the Cadillac and Studebaker V8s had essentially the same bore centers: (Cad: 4.5625″, Stude: 4.50″).

I found a vintage review that says that the ’57 GH weighed 40 lbs less on the front end. But that still raises the question as to whether the ’57 they used for comparison had an automatic or manual. I strongly suspect it was an automatic, which means there was undoubtedly a greater difference in the case of a manual.

Studebaker revised the rear suspension in ’57 and made a few other changes in the suspension tuning to improve its handling and to help compensate for the intrinsic front-heaviness.

Studebaker came close to offering a dealer-installed Jet Streak engine option in 1956 that would have included a four-barrel carb from the Packard Caribbean that boosted power to 330 hp. It was even assigned a part number, 1541805. There was also talk of putting the Packard 374 cu.in. engine in the Hawk for 1957 (Packard intended to increase power and maybe displacement again in ’57 as they had in ’56), but neither the Jet Streak or the 374 would happen.

I’d be more than happy to have the Studebaker.

Something about the basic shape of the Lowey coupe has always intrigued me and I find something to like about all of its iterations.

Near the end of the Studebaker era, there was a dealer in town who had a couple of GHs in a dusty showroom window. When I rode by on my bike, I don’t believe I can remember ever seeing a staff member inside the store, or for that matter, the windows ever cleaned. One day the windows were brown papered over and that was that.

I quite liked the look of the grilles of those cars, very stylish and appealing. Kind of timeless in their design. Some of the best looking cars of their time.

It’s always fun to go back to “what was” , when Studebaker and Packard “merged” they had a huge asset in the fact that they had two in house V-8’s, AMC had none, Kaiser-Willys had none, S-P had 2. A brand new big block and a new factory to build it in (Packard Utica, MI), and a 5 year old “small” block. These were enough engines, with up grades to keep them modern for 20 + years. They lost the ball, the “small” block served them well until the end, and the “big block” I think ended up in fire engines somewhere, too bad.

I think that you might be thinking of Pierce Arrow having their engines live on in fire trucks.

I’m afraid that by 1957, I would have problems buying anything from Studebaker, which increasingly looked like it wouldn’t survive another year. The dealers were often small. The corporation was failing. The merger with Packard was a flop. The Packard was an old design. The Studebaker Hawk was five years old. Chrysler’s products were big, bold and popular. The little Hawk looked like warmed over mashed potatoes. The design no longer looked new.

The ’57 Rambler Rebel was cheaper and faster. 0-60 in 7.2 by one magazine’s test. But I doubt that it would have handled nearly as well as the Hawk.

And why would you think it would not handle as well?

It seems a shame that the Packard V8 had such a limited production life. What do people think of this engine in retrospect?

As far as I know, it’s held in quite high regard. I think it might have had a couple of minor teething issues at first. And it was the polar opposite of the Studebaker in terms of room for future growth. It had a very ample bore center, which meant it could have had its displacement increased possibly close to 500 CI.

Many of Studebaker’s decisions remind me that there were board members who didn’t really want to be in the car business.

As if their slogan should have been:

Studebaker, the Car Company not very Fond of Building Cars.

Studebaker: When Horses and Buggies Come Back, We’ll be Ready!

The Golden Hawk anticipated both personal luxury coupes and muscle cars. Well personal-luxury coupes anyway, and the later R2 and R3 engine options yielded performance comparable to anything the big 3 was selling in 1963. Nonetheless, the four-seat Thunderbird would become the definitive PLC a year later, and the hi-po engines were gone by the time the muscle car phenomenon really took hold.

Are those things above the headlamps turn signal indicators or just hood ornaments?

Asbestos lining disc in the clutch, yikes…

How many 5-seater cars seat three people up front, two in back? I can’t think of any other modern examples.

I wasn’t aware that the Mercedes-Benz agreement included sharing engineering as well as dealerships. Studebaker could have used that Bosch fuel injection discussed in the article. Mercedes can keep their swing-axles though…

Nothing unusual about the use of asbestos in clutch and especially brake linings. It was also used in exhaust manifold gaskets. It wasn’t until about thirty years ago when less toxic materials were adopted. Professional mechanics were aware of the asbestos. Good work practices consisted of never using compressed air to clean out brake mechanisms and I’d imagine clutch bell housings. Brake cleaner spray was used, then wiped off with rags, keeping the fibers out of the air. Asbestos was also used in may household materials. You’ve got to be careful when working on older cars and houses.

Good work practices consisted of never using compressed air to clean out brake mechanisms

I have vivid memories of the mechanic at the Sunoco station I worked at as a teen blowing out the brake mechanisms, creating a nice thick brown cloud that enveloped him. The lit cigarette in his mouth was almost obscured. 🙂

Yeah, that little tidbit un the article about an agreement to share suspension designs and body work with Mercedes is fascinating. The story itself hints at Hawks to come with Mercedes-derived independent rear suspensions, Bosch fuel injection and who knows what else. Was there ever a single prototype of something like that?

The Golden Hawk often gets compared with the Chrysler 300. Ironically, had Studebaker been able to follow through on the proposed design collaboration with Daimler-Benz, the result would have had mixed German-American DNA a bit like today’s Chrysler 300.

The test car looks like the 1957 Golden Hawk that I owned for nine years. It was black with three speed and overdrive, along with power windows and power seat.

The Golden Hawk was truly a unique offering in 1956-57. It came so close to several niches that eventually became quite popular – the personal luxury coupe, the muscle car, and even the pony car (had they been able to lop a foot out of the wheelbase up front).

Truthfully I think the 58 Thunderbird spelled the beginning of the end for the Hawk.

The Avanti essentially was a pony car, except the price was too high and they couldn’t have built them in volume even if the demand was there. Still, the configuration (sporty long hood/short deck/low roof coupe with powerful V8/rear drive built on a mainstream compact sedan platform) would become the standard pony car template. Had they been priced similarly, and had South Bend-produced Studes held on a bit longer, an Avanti R2 or R3 could have given the Mustang 289 a run for the money. I prefer the Mustang’s exterior styling, but the Avanti was much nicer on the inside, Also, the 70-1/2 Camaro stole the Avanti’s dashboard.

Anyway, if I were reconfiguring the Hawk to compete with pony cars, I’d leave the front wheelbase alone and shorten the wheelbase in the back, lopping off some of the rear overhang as well. You want that long hood on a pony car (or a PLC for that matter).

I’ll second what la673 is saying, get a profile look at a 1st gen Mustang and it is definitely LONG HOOD and SHORT DECK.

That’s part of the pony car profile.

As the HAWK stands there is something about it that says “man’s car” – Dad drives it daily but there’s still enough room to pile the kids in and put all your picnic supplies in the trunk heading out for a Sunday afternoon.

Studebaker had 18 head bolts per side, not 16 as someone mentioned earlier. It also had much larger bearing area than most competitors . Also, the thrust surface is the front main where most accessory load is. The SAE papers on the design of the Studebaker engine mentions all these and more. If anyone is arguing what they were thinking when it was designed, it is all spelled out in black and white. It was made for 14:1 compression, and Hemi heads were even considered but discounted due to costs. For the life of me I don’t understand, but economy was pushed far more than performance when it was designed. The horsepower wars were in the far off distance. The fact that later versions of the same basic design tromped (and still do) most competitors of ANY make. If you are going to push your Chevy agenda then you better know what you are talking about. Research the Pure Stock Muscle Car Drags held in Stanton Michigan, and you will see certified stock Studebakers STILL walk away from challengers left and right.

it is all spelled out in black and white. It was made for 14:1 compression,

Where, exactly? Could you please show us the black and white, other than from the various articles written in later years that I have seen too, but don’t actually source anything from the company or the engineers that designed it?

Here’s the paper given by its designers to the SAE, describing the creation and development of the new V8.

https://www.studebaker-info.org/MAA/HR0852P28/hr0852p28.html

There’s talk of it being easy to increase its compression ratio from 7.0 to 8.5:1. But there’s nothing in that SAE paper about designing it for 14:1 compression.

I’m not saying that it might have been a vague consideration, but on the other hand, there’s nothing I’ve seen in black and white that supports that assumption, which is constantly being regurgitated.

There’s no Chevy agenda here. I have lots of respect for the Stude V8. But would you like to compare the total respective wins of the SBC and the Stude V8 in drag racing history and various racing arenas?

There’s a lot more to racing- even in a straight line than just horsepower.

“High fin improves rear looks — adds some stability”

As interesting as the Golden Hawk and its supercharging is to us now, it was a peripheral model at best. It was fielded on the hope that a halo car would entice potential buyers into the showroom where they’d find the mundane Studebaker sedans and wagons that were the company’s bread and butter, and buy one. The Hawks were the only thing they had going for them to differentiate themselves from American Motors.

A larger displacement than 289 was unnecessary given they consistently under-sized their cars in terms of width, and with the 1953 line went too far with Loewy’s “Weight is the Enemy” mantra to the point their cars were perceived as flimsy. When they ginned-up the Lark under extreme financial distress, they had only to truncate the body and frame, the width was already that of a compact car.

The overweight engine situation was the result outdated foundry methods left over from ordinance and pre-war work. iirc, Studebaker foundry cast engine blocks for the American Motors V8 into the 1960’s under contract. By the 1960’s, the Lark compact needed a new generation of engines built with modern casting technology but the BoD wasn’t going to throw any more money at the unprofitable automotive division.

The best thing one can say about the Studebaker V8 is that among the independents, it was the first, it was durable and relatively trouble-free, that it kept their cars somewhat competitive until the new generation of compacts arrived for 1960 at which time it immediately became an also-ran, The engine had one last hurrah in the Avanti’s, Super Larks and Super Hawks before the lights went out.

↑↑↑↑↑

The profile of the Hawk puts me in mind of the Volvo P1800 for some reason. They both come off as slightly odd ducks (albeit attractive ones), but odd by the same hand.